UF Plant - Ultra Filtration Plant

A UF Plant, or Ultrafiltration Plant, is a water treatment system that utilizes ultrafiltration technology to remove suspend solids, bacteria, viruses, and other particulate matter from water. Ultrafiltration is a membrane filtration process that operates on a pore size range between 0.01 to 0.1 microns, making it effective in removing particles of various sizes.

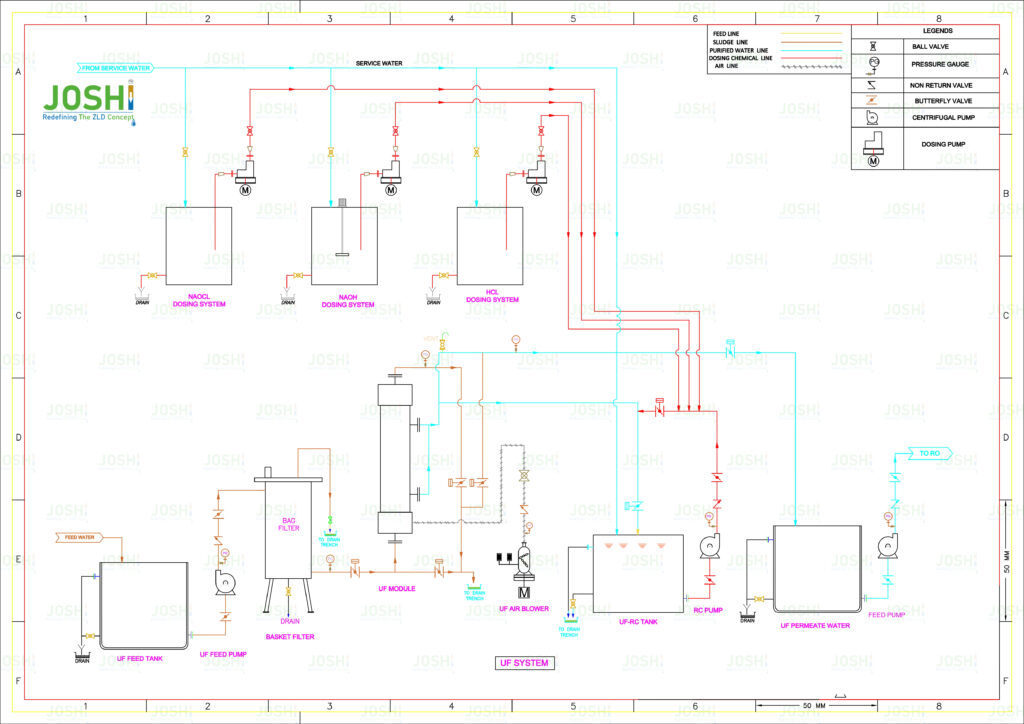

System Components

Membrane Modules : UF Plants consist of membrane modules, which contain a series of hollow fiber or spiral-wound membranes. These membranes have microscopic pores that allow water molecules to pass through while retaining suspend solids, bacteria, and other contaminants.

Feed Pump: A feed pump is use to provide the necessary pressure to drive water through the membrane modules. The pump ensures a consistent flow rate and maintains the requir operating pressure for the ultrafiltration process.

Backwash System: To prevent fouling and maintain the performance of the membranes, UF Plants often have a backwash system. This system periodically reverses the flow of water to flush away accumulate particles and debris from the membrane surface.

Control System: A control system monitors and controls various parameters of the UF Plant, such as pressure, flow rate, and backwash cycles. It ensures the system operates within the desir parameters and can provide alarms or alerts in case of any deviations or issues.

Process Steps

Filtration: Water is pressure and force through the ultrafiltration membranes. The membranes act as a physical barrier, effectively removing suspend solids, bacteria, viruses, and other particulate matter from the water. The filter water, known as permeate, passes through the membrane pores and is collecte for further treatment or distribution.

Concentrate Disposal: The water that does not pass through the membrane, containing the retain contaminants, is referre to as the concentrate or retentate. This concentrate stream is diverted and either discharged or directed to further treatment processes, depending on the specific requirements of the application.

Significance & Advantages

Drinking Water Treatment: UF Plants are employ in the treatment of surface water, groundwater, or other water sources to provide safe and high-quality drinking water. They can effectively remove turbidity, pathogens, and suspended solids, ensuring the water meets regulatory standards.

Wastewater Treatment: UF Plants are utilized in wastewater treatment processes, especially in tertiary treatment or water reuse applications. They can remove solids, bacteria, and some viruses, enhancing the quality of the treat water for various reuse purposes.

Industrial Applications: UF Plants find application in various industrial processes, such as food and beverage production, pharmaceutical manufacturing, and electronics manufacturing. They assist in the removal of particulate matter, clarification, and process water treatment.

UF Plants offer advantages such as high removal efficiency, compact design, and relatively low energy consumption compare to other filtration technologies. Regular maintenance, including membrane cleaning and replacement, is necessary to ensure the continue performance and longevity of the UF Plant.