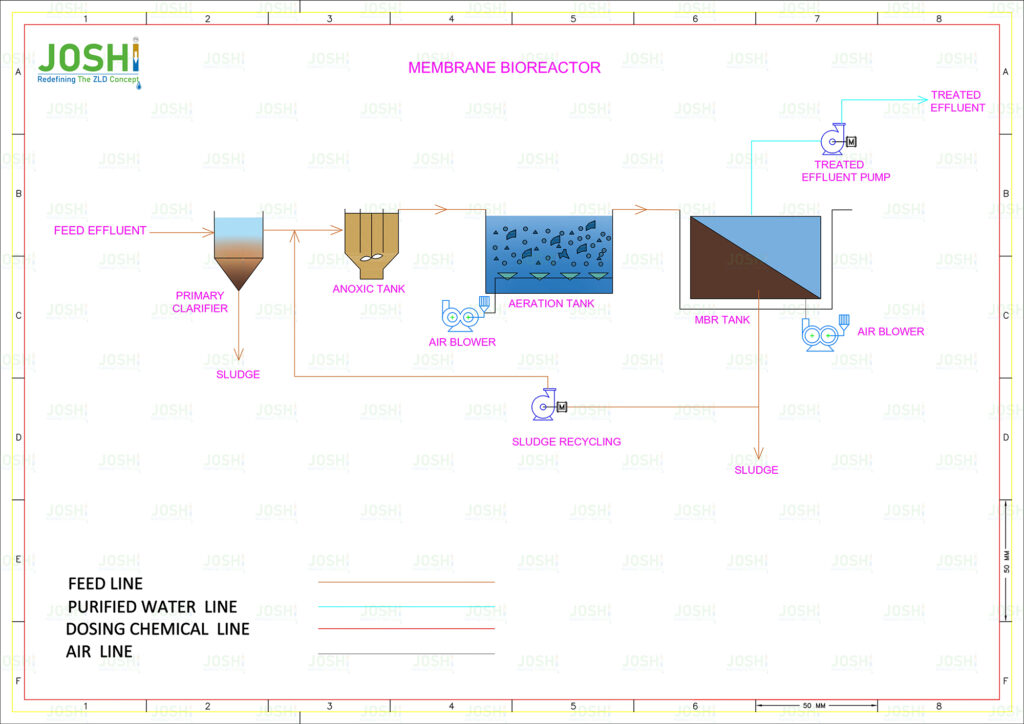

Membrane Bio Reactor (MBR)

A membrane bioreactor (MBR) is an advance wastewater treatment technology that combines biological treatment processes with membrane filtration. It integrates the activat sludge process, where microorganisms are used to biologically degrade organic matter, with a membrane filtration system that serves as a physical barrier to separate solids and microorganisms from the treated water.

System Components

Bioreactor: The bioreactor serves as the vessel where the activate sludge process takes place. It contains the microorganisms responsible for the biological degradation of organic matter. Aeration and mixing are provide to maintain an optimal environment for the microorganisms.

Membrane Filtration: The membranes are locate within the bioreactor or in a separate membrane tank. The mix liquor is circulated across the membranes, creating a pressure difference that drives the treat water through the membranes. The retain solids and microorganisms accumulate on the membrane surface.

Filtration Control: To prevent fouling and maintain membrane performance, the MBR system employs various strategies such as back washing, air scouring, and periodic membrane cleaning. These measures help to remove accumulated solids and maintain the permeability of the membranes.

Solids Separation: The solids and microorganisms retain by the membranes form a concentrate sludge known as membrane solids or biomass. A portion of this sludge is typically recycle back to the bioreactor to maintain a healthy microbial population and ensure efficient treatment.

Process

In an MBR system, the wastewater to be treat enters a bioreactor where it is mixed with a culture of microorganisms, similar to the activated sludge process. The microorganisms in the bioreactor metabolize and break down the organic matter in the wastewater.

However, unlike traditional activated sludge systems, MBRs employ membranes to separate the treated water from the mixed liquor, which consists of the microorganisms and suspended solids. The membranes used in MBRs are typically made of polymeric materials and have small pore sizes, ranging from microfiltration to ultrafiltration.

The membrane filtration stage occurs simultaneously with the biological treatment process. The membranes act as a physical barrier, allowing the permeation of treat water while retaining suspend solids, microorganisms, and pathogens. This results in a high-quality effluent that is free from most particles and microorganisms.

Significance & Advantages

High-Quality Effluent: MBRs produce a high-quality effluent that meets stringent water quality standards. The membranes effectively remove suspend solids, pathogens, and most particulate matter, resulting in clearer and cleaner water.

Compact Footprint: MBR systems have a smaller footprint compare to conventional treatment processes since the membrane filtration eliminates the secondary clarifiers or settling tanks.

Process Flexibility: MBRs can handle variations in flow rate and influent characteristics, making them suitable for both municipal and industrial wastewater treatment applications.

Nutrient Removal: With appropriate process design, MBRs can be configure to achieve nutrient removal, including nitrogen and phosphorus, providing an additional level of treatment.

Target Impurities

- COD

- BOD

- Nutrient

- NO2

- NO3

- Phosphorus