Tube Settler

A tube settler is a type of wastewater treatment equipment use to enhance the settling process in sedimentation tanks or clarifiers. It consists of a series of inclined tubes or channels that provide a large settling area within a relatively small space.

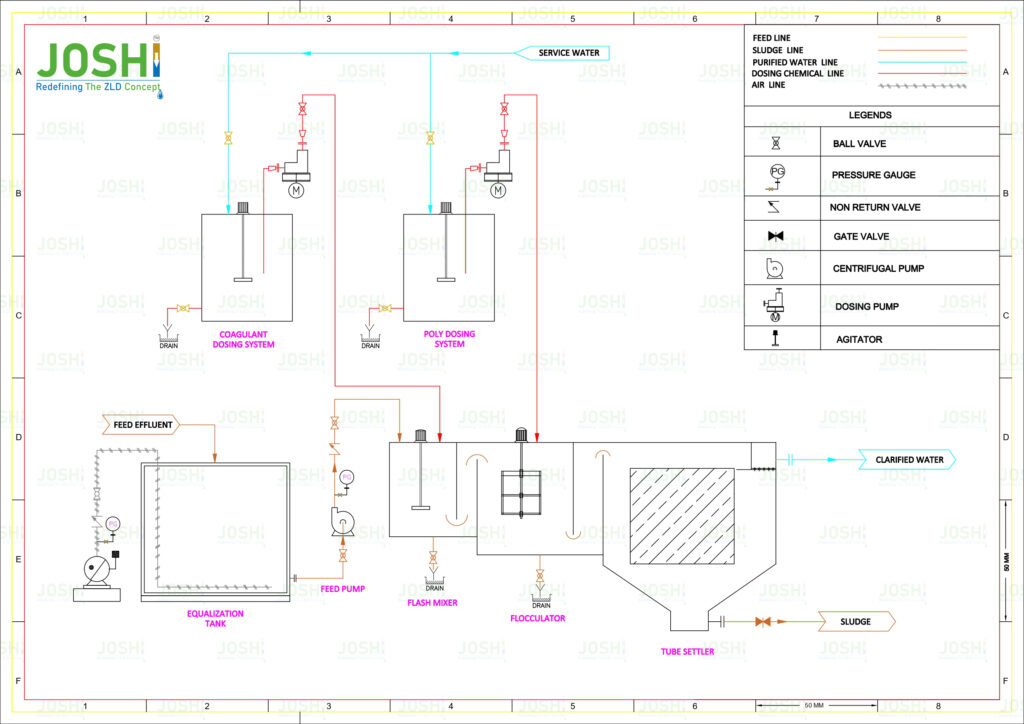

Process

The tube settler works by utilizing the principles of laminar flow and gravity settling. The wastewater or water to be treat enters the settling tank and flows through the incline tubes of the tube settler. The tubes are typically made of plastic and are arrang in a parallel configuration.

As the water flows through the tubes, the suspend solids present in the water begin to settle due to gravity. The incline tubes provide a longer settling path, allowing for more time for the solids to settle. The settl solids slide down the tubes and accumulate at the bottom of the tank. The clarify water exits the Lamella Clarifier from the top and can be further treated or discharge as per the required standards. The sludge collect in the sludge hopper is periodically remove for further treatment or disposal.

After the flocculation stage, the water proceeds to the settling stage within the same tank. The velocity of the water flow is reduc, allowing the formed flocs to settle to the bottom of the tank by gravity. The settle particles, along with the form sludge, are collect and remove as sludge from the tank.

The clarify water, known as the supernatant, is collected from the upper part of the tank, typically using a collection mechanism or launder system. It is then further treat through processes such as filtration, disinfection, or other advanc treatment methods to achieve the desire water quality.

Significance

The use of tube settlers in wastewater treatment has several advantages. They increase the effective settling area, leading to improv sedimentation and separation efficiency. Tube settlers also promote the formation of a laminar flow pattern, reducing turbulence and enhancing the settling process. Additionally, they can handle higher flow rates and solids loading compared to traditional settling tanks.

Improved Settling: The flocs form during flocculation are larger and heavier than individual particles, which enhances the settling process and improves the efficiency of suspend solids removal.

Simplicity and Cost-effectiveness: Having a single tank for both flocculation and sedimentation simplifies the treatment process and reduces the equipment and infrastructure require, resulting in cost savings.

Flexibility: The mixing intensity and settling characteristics can be adjust based on the specific treatment requirements by controlling the speed and configuration of the mechanical agitators or paddles.

Targeted Impurities

- TSS

- Turbidity

- BOD

- Colloidal Particles

- Partial Color

- Grit

- Chemical Sludge

- Hardness

- Heavy Metals