MED - Multiple Effect Distillation

Multiple Effect Distillation (MED) is a thermal desalination process used to convert saline water, such as seawater, into freshwater by utilizing the principle of evaporation and condensation. It is a widely employe method of large-scale desalination and is known for its energy efficiency compared to other thermal desalination processes.

Process Mechanism

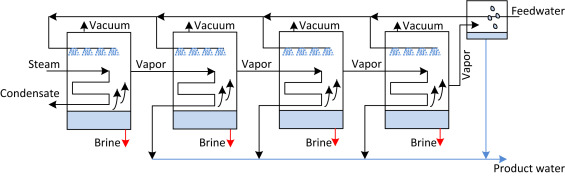

In the MED process, the saline water is subject to multiple stages or effects of evaporation and condensation. Each stage operates at a progressively lower pressure, which allows for the utilization of the waste heat or steam generate from the previous stage to drive the evaporation process in subsequent stages. The number of effects refers to the number of evaporation stages in the MED system

Process Steps:

Preheating : The saline water is preheate by utilizing waste heat or steam generate from the MED process. This preheating helps to reduce the energy requirements of the subsequent evaporation stages.

Evaporation : The preheate saline water enters the first effect, where it is heated under reduce pressure. The heat causes a portion of the water to evaporate, leaving behind a more concentrated brine. The vapor produce in the first effect then moves on to the next effect, where it condenses and transfers its latent heat to the seawater in that effect, causing further evaporation. This process is repeate in subsequent effects, with each stage operating at a lower pressure and temperature.

Condensation : In each effect, the vapor produce from the previous stage is condense by cooling surfaces or heat exchangers, transferring its heat to the incoming seawater. The condensation of the vapor generates freshwater, known as distillate, while the remaining brine becomes increasingly concentrate.

Brine Disposal : The concentrate brine, which remains after the evaporation process, is collecte and discharge back into the sea or dispose of in an environmentally responsible manner.

Significance & Advantages

The MED process utilizes the heat generate from the condensation of vapor in each effect to drive the evaporation process in subsequent effects. This heat recycling mechanism makes the MED process more energy-efficient compare to single-effect distillation processes. However, it requires a reliable source of waste heat or steam to operate effectively.

MED desalination plants are capable of producing large quantities of freshwater and are commonly use in regions where waste heat or steam is readily available, such as in power plants or industrial processes. The energy efficiency and scalability of the MED process make it a viable option for large-scale water supply projects, especially in areas where access to freshwater is limited.