ACF - Activated Carbon Filter

An activate carbon filter, also known as a carbon adsorption filter, is a type of filtration ACF system use in wastewater treatment to remove organic contaminants, dissolve gases, and certain chemicals from water.ACF utilizes activate carbon as the filtration media, which has a high affinity for adsorbing a wide range of organic compounds.

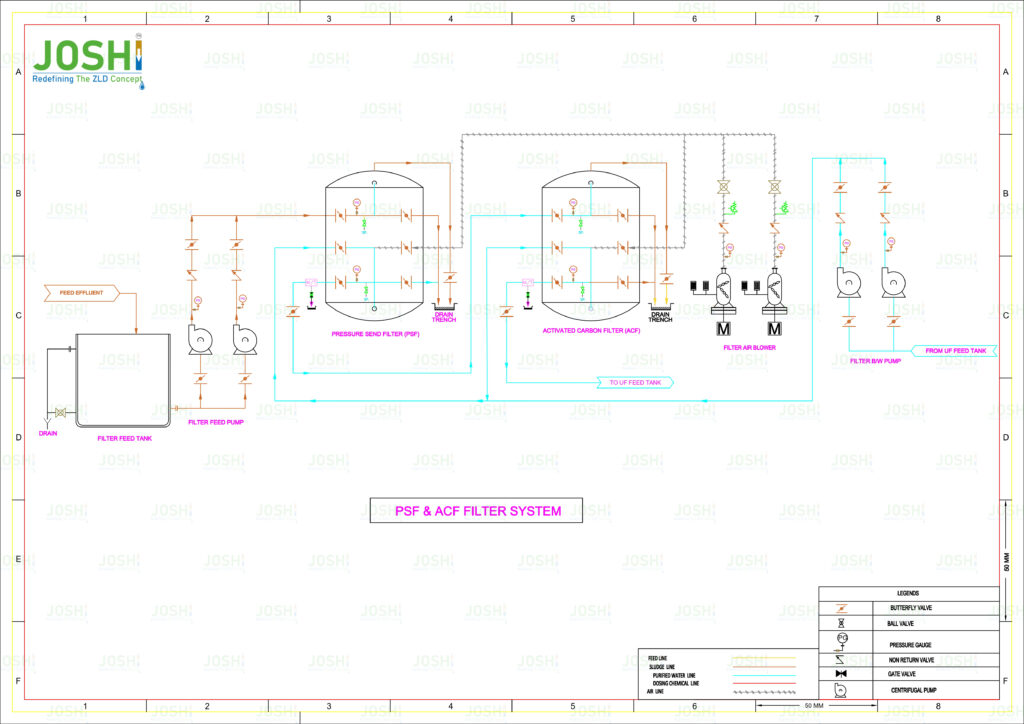

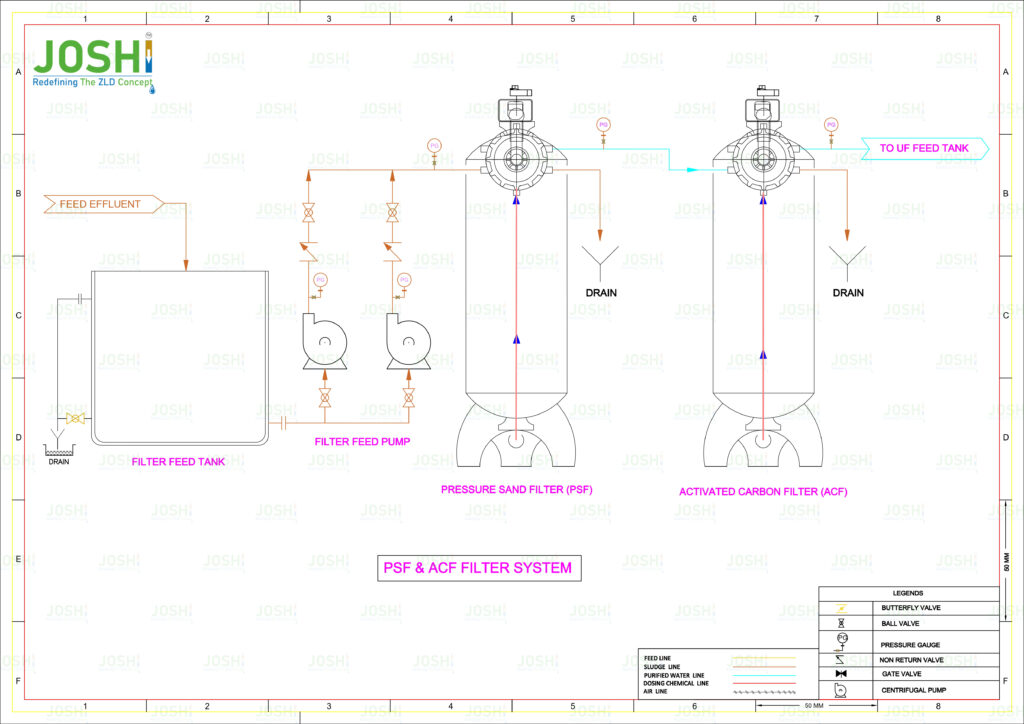

System Components

Filter Vessel: The filter vessel is a cylindrical or rectangular tank that contains the activate carbon media. Design to withstand the operating pressure of the system. Vessel is usually made of steel or reinforce concrete and is equippe with inlet and outlet connections.

Activated Carbon Media: Activate carbon is a highly porous material with a large surface area that provides adsorption capacity. Derive from various sources such as coconut shells, wood, or coal, and is process to activate its adsorption properties. The activate carbon media is usually in granular or powder form and is place in the filter vessel.

Distribution System: Distribution system ensures even distribution of the influent wastewater across the activate carbon. Typically consists of underdrains, lateral pipes, and nozzles that distribute the water uniformly over the surface of the carbon media.

Backwash System: Backwash system is incorporated into the activate carbon filter to periodically clean the carbon media and remove accumulate solids. Includes a backwash pump, valves, and a wash water collection system. The backwashing process involves reversing the water flow or using air or water mixtures to agitate the carbon bed and remove trapp particles.

Control System: Control system monitors and regulates the operation of the activate carbon filter. It controls flow rates, backwashing cycles, and other parameters to optimize the filtration process and ensure efficient operation

Process Description

Adsorption: The influent wastewater enters the filter vessel through the inlet connection and is evenly distribute across the active carbon by the distribution system.

As the water passes through the carbon media, organic compounds, dissolve gases, and certain chemicals are adsorbe onto the surface of the carbon particles. This adsorption process removes contaminants from the water.

Accumulation of Contaminants: Over time, the activate carbon media becomes saturate with adsorbe contaminants, reducing its adsorption capacity. This indicates the need for regeneration or replacement of the carbon media.

Regeneration or Replacement: Depending on the type and concentration of contaminants, the activate carbon media may need to be regenerate or replace periodically to maintain its adsorption efficiency. Regeneration involves washing the carbon media with appropriate chemicals or steam to remove adsorb contaminants and restore its adsorption capacity. In some cases, the carbon media may be replace entirely.

Significance & Advantages

Effective Organic Contaminant Removal: This Activate carbon has a high affinity for organic compounds, making it highly effective in removing a wide range of organic contaminants, including pesticides, solvents, and pharmaceuticals.

Adsorption of Dissolved Gases: Activate carbon can also adsorb dissolve gases, such as volatile organic compounds (VOCs), chlorine, and hydrogen sulfide, improving the water quality and reducing odor.

Chemical Removal: Certain chemicals, such as chlorine and chloramines, can be adsorbe by activating carbon, providing chemical removal capabilities.

Versatility: Carbon filters can be use in various applications and treatment scenarios, including municipal water treatment, industrial wastewater treatment, and groundwater remediation.

Odor Control: The adsorption of organic compounds and gases helps to mitigate unpleasant odors in wastewater.

Targeted Impurities

- dissolved gases

- volatile organic compounds (VOCs)

- chlorine

- hydrogen sulfide

- Odor

- COD

- Color