DAF - Dissolved Air Floatation

DAF stands for Dissolve Air Flotation, which is a wastewater treatment process use for the separation and removal of suspende solids, fats, oils, greases, and other contaminants from wastewater. DAF systems are commonly employ in industrial, municipal, and commercial wastewater treatment plants.

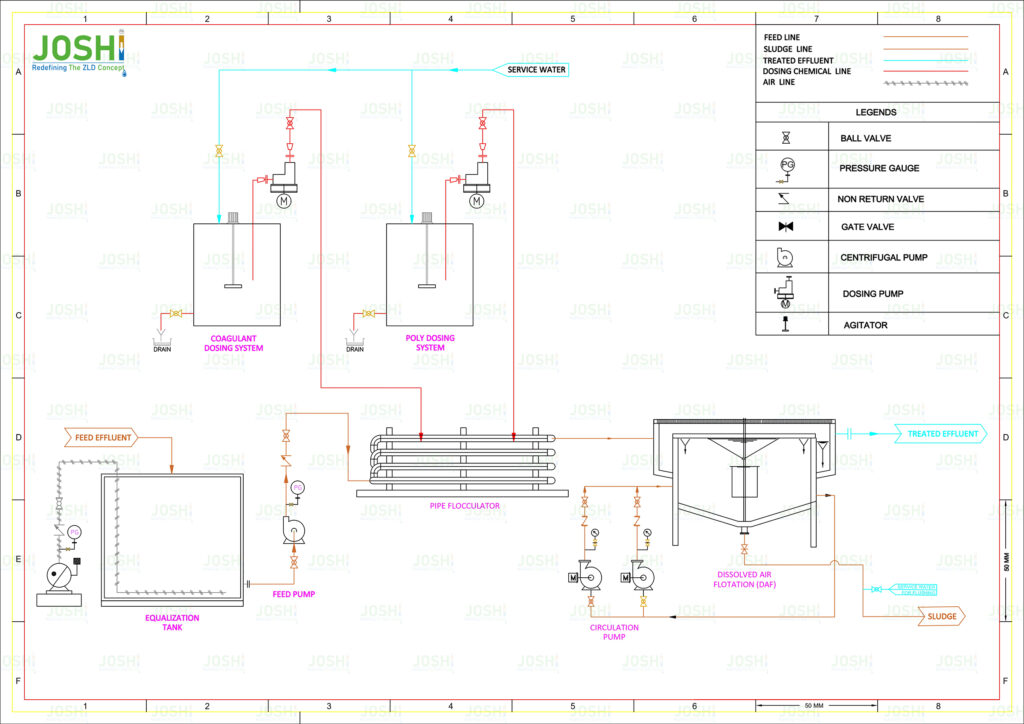

Process Steps

Coagulation and Flocculation : In some cases, prior to DAF, a coagulant or flocculant may be add to the wastewater to facilitate the aggregation of small suspend particles into larger flocs. This helps improve the efficiency of the flotation process.

Mixing and Contact : The wastewater is introduce into a flotation tank or basin where it is mix with a recycle stream of water and/or chemicals. This mixture creates a supersaturat solution of dissolve air.

Release of Pressure : The supersaturate solution is then rapidly release into the flotation tank, causing the air to come out of solution and form tiny bubbles throughout the tank.

Bubble Attachment and Rise : The fine air bubbles rise through the tank, carrying the suspend solids and contaminants with them. The particles adhere to the bubble surfaces due to their hydrophobic nature or through physical or chemical interactions.

Float Removal : The float layer, consisting of the particles attache to the rising air bubbles, accumulates at the surface of the tank. Mechanical skimmers or weirs are used to continuously remove and collect this float layer.

Clarified Effluent : The treat effluent, now clarifie and with reduce suspend solids and contaminants, exits the flotation tank through an outlet.

Significance & Advantages

DAF systems are highly effective in removing a wide range of contaminants, including suspend solids, fats, oils, greases, algae, and certain dissolve substances. They are particularly useful in applications where traditional sedimentation processes may be ineffective or inefficient. DAF systems can be tailored to meet specific treatment goals and can be use as a standalone process or as part of a larger wastewater treatment system.

Overall, micro screens play a vital role in wastewater treatment by providing an additional level of filtration to ensure the removal of very fine particles, suspend solids, and microorganisms, thus improving the overall water quality and protecting downstream treatment processes and equipment.

Targeted Impurities

- suspend solids

- fats

- oils

- greases

- algae

- certain dissolve ubstances