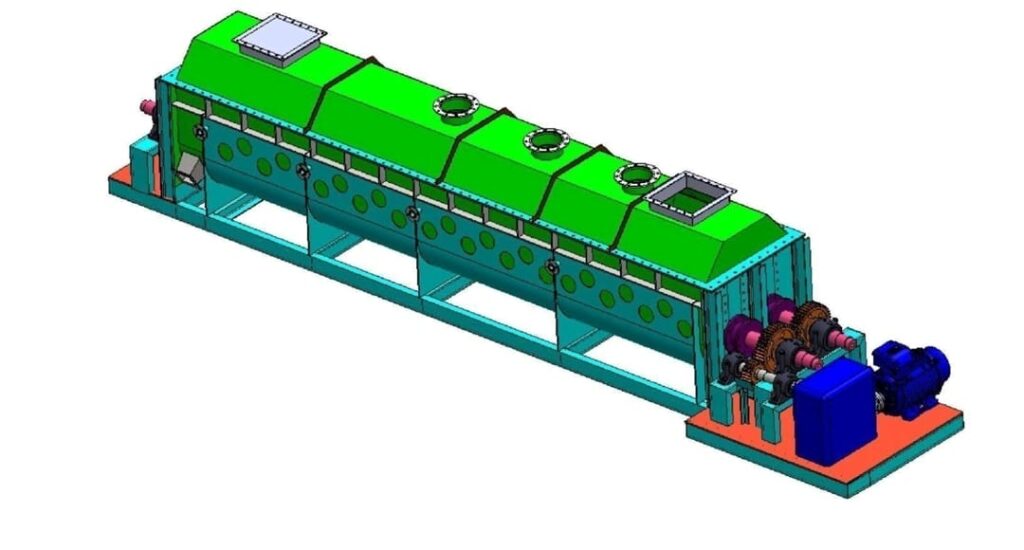

Paddle Dryer

In wastewater sludge handling, a paddle dryer, also known as a paddle dryer mixer, is a specialize drying device used to reduce the moisture content of sludge. It is a type of indirect dryer that employs paddles or agitators to mix and expose the sludge to heate surfaces, facilitating moisture evaporation.

System Components & Process Steps

Vessel/Housing : The cylindrical vessel or housing provides a contained environment for the sludge drying process. It is typically equippe with heating surfaces or jackets to provide indirect heat transfer.

Rotating Shaft : The shaft, driven by a motor, rotates within the vessel and carries the paddles or agitators. The rotation of the shaft ensures uniform mixing and distribution of the sludge within the dryer.

Heating Surfaces : The vessel may have heating surfaces, such as steam jackets or coils, locate on the walls or within the dryer. These surfaces transfer heat to the sludge indirectly, promoting the evaporation of moisture.

Paddles/Agitators : The paddles or agitators attache to the rotating shaft help break up any clumps, ensure even mixing, and expose a larger surface area of the sludge to the heated surfaces.

Moisture Evaporation : As the sludge is agitate and mix by the paddles, it comes into contact with the heat surfaces. The heat from the surfaces promotes the evaporation of moisture from the sludge.

Discharge : Once the drying process is complete, the drie sludge is discharge from the paddle dryer through an outlet.

Significance & Advantages

Paddle dryers offer advantages such as efficient heat transfer, gentle handling of the sludge, and the ability to handle high-viscosity or sticky sludge. They are suitable for various sludge types, including municipal wastewater sludge and industrial sludge.

The paddle dryer design allows for precise control of the drying process, including temperature, residence time, and mixing intensity. This flexibility enables the optimization of the drying conditions to achieve the desired moisture reduction while maintaining the quality of the dried sludge.