Micro Screen

In wastewater treatment, a micro screen, also known as a microfiltration screen or micro strainer, is a type of filtration device use to remove very fine particles, suspend solids, and microorganisms from the wastewater stream. It is an advance filtration technology that operates on a smaller scale than conventional screens.

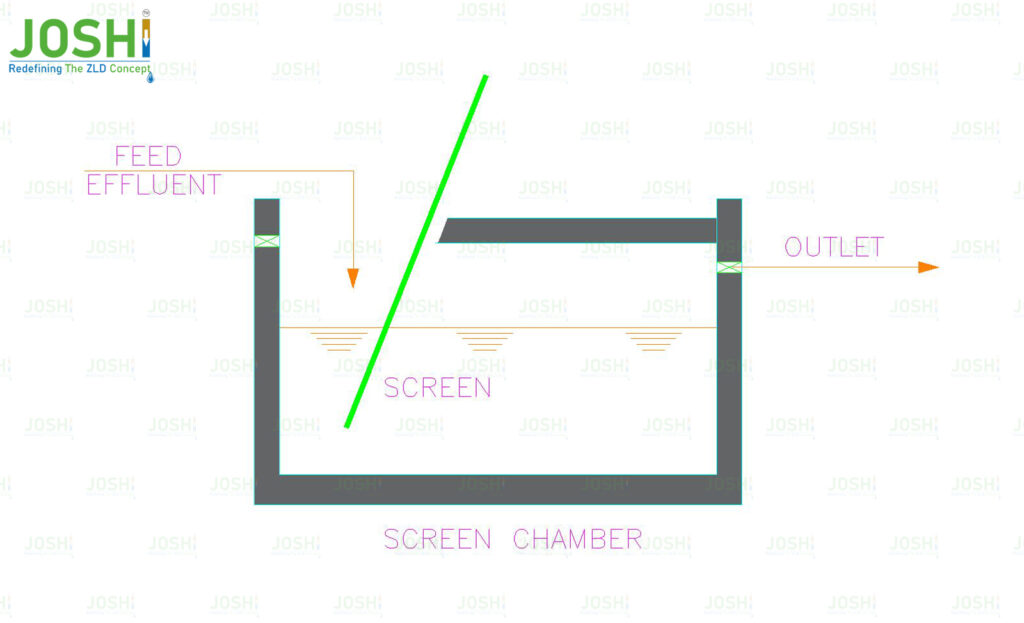

Process

Wastewater is pass through the micro screen, and the suspend particles and microorganisms are trappe on the surface of the screen or within its pores. The clean water, with significantly reduce levels of impurities, passes through the screen and continues to the next stage of the treatment process. To maintain the performance of micro screens, periodic cleaning or backwashing may be require to remove accumulate solids and prevent clogging. This can be done using water jets, air scouring, or other cleaning mechanisms.

Significance & Advantages

Micro screens are commonly use in advance wastewater treatment applications, such as tertiary treatment or wastewater reclamation, where a high level of filtration is require to produce high-quality effluent. They are also used in industrial processes where fine particle removal is necessary.

Overall, micro screens play a vital role in wastewater treatment by providing an additional level of filtration to ensure the removal of very fine particles, suspend solids, and microorganisms, thus improving the overall water quality and protecting downstream treatment processes and equipment.

Target Impurities

- Fine Particles

- Suspende Solids

- Microorganisms