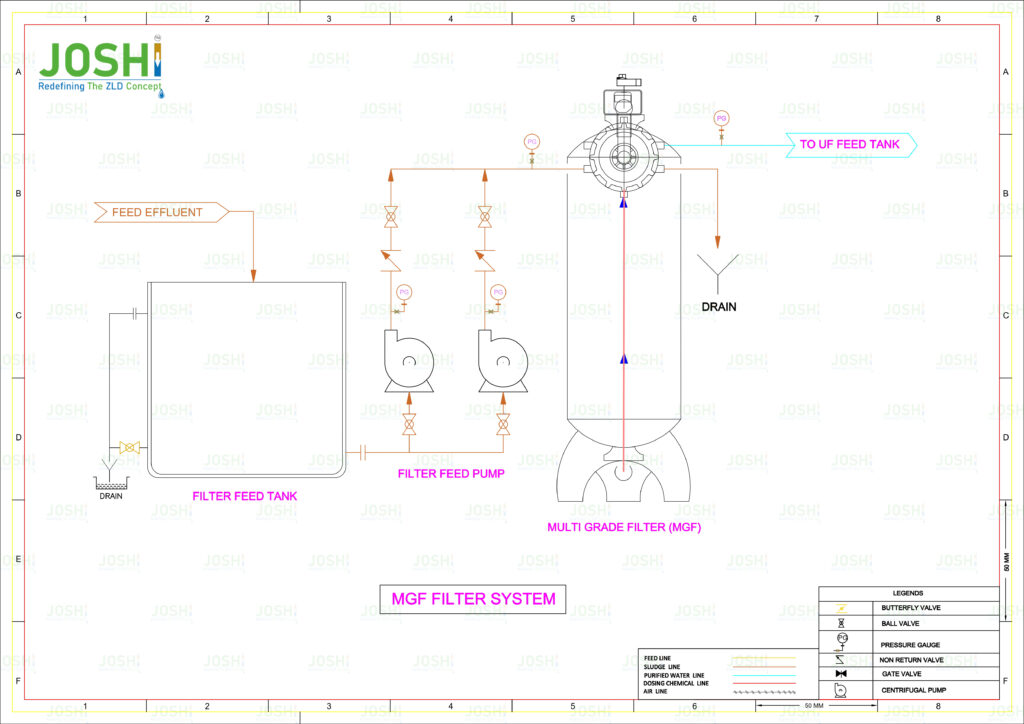

MGF - Multi Grade Filter

A multigrade filter is a type of filtration system use in wastewater treatment to remove suspende solids and turbidity from water. It employs a bed of filter media with varying particle sizes, allowing for efficient filtration and improve solids removal compare to single media filters.

System Components

Filter Vessel: The filter vessel is a cylindrical or rectangular tank that contains the filter media. It is design to withstand the operating pressure of the system. The vessel is usually made of steel or reinforced concrete and is equip with inlet and outlet connections.

Filter Media: The multigrade filter utilizes a combination of different grades of filter media with varying particle sizes. The media layers are arrange in a specific sequence within the filter vessel. Commonly used media include anthracite coal, silica sand, and garnet. The media with larger particle sizes are place at the top, followed by finer media at the bottom.

Distribution System: The distribution system ensures even distribution of the influent wastewater across the filter media. It typically consists of underdrains, lateral pipes, and nozzles that distribute the water uniformly over the surface of the media.

Backwash System: A backwash system is incorporate in the multigrade filter to periodically clean the filter media and remove accumulated solids. It includes a backwash pump, valves, and a wash water collection system. The backwashing process involves reversing the water flow and fluidizing the media to dislodge trappe particles.

Control System: A control system monitors and regulates the operation of the multigrade filter. It controls flow rates, backwashing cycles, and other parameters to optimize the filtration process and ensure efficient operation.

Process Description

Filtration: The influent wastewater enters the filter vessel through the inlet connection and is evenly distribute across the top layer of larger media by the distribution system. As the water flows through the media layers, suspende solids and turbidity are trappe within the filter.

Particle Capture: The larger media at the top layer act as a pre-filter, removing larger particles and providing a protective layer for the underlying finer media. The finer media in the lower layers provide additional filtration and capture smaller particles.

Accumulation of Solids: Over time, the suspende solids accumulate in the filter media, causing an increase in pressure drop across the filter. This indicates the need for backwashing to restore the filter’s efficiency.

Backwashing: When the pressure drop reaches a predetermine level, the control system initiates a backwash cycle. The backwash pump reverses the water flow, fluidizing the media bed from the bottom to the top. This action dislodges and removes the trappe solids, which are carrie out through the wash water collection system.

Rinse and Return to Service: After backwashing, a rinse cycle may be performe to settle the filter media and remove any remaining impurities. The filter is then return to the filtration mode, and the cycle continues.

Significance & Advantages

Improved Filtration Efficiency : The combination of different media grades allows for efficient filtration and improve solids removal compare to single media filters.

Longer Filter Run Time: The multigrade configuration extends the duration between backwashing cycles, reducing operational costs and water consumption.

Flexibility and Adaptability: Different combinations of media grades can be use to tailor the filtration system to specific wastewater characteristics and treatment goals.

Easy Maintenance: Backwashing helps maintain the performance of the filter media and extends its lifespan.

Targeted Impurities

- TSS

- Turbidity