Multi Effect Evaporators (MEE)

A multi-effect evaporator is a specialize type of evaporator used in wastewater treatment processes to remove water from a liquid solution or wastewater stream. It operates on the principle of utilizing multiple stages or effects to progressively evaporate water and concentrate the dissolve solids or contaminants in the remaining liquid.

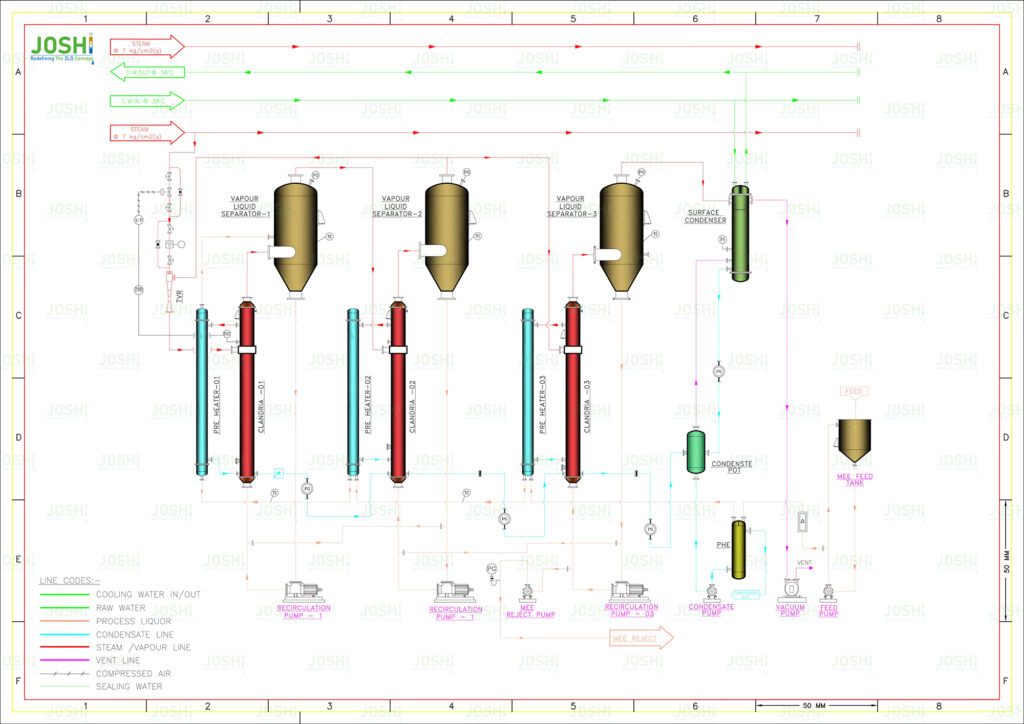

System Components

The multi-effect evaporator typically consists of a series of evaporator vessels or stages, where each stage operates at a different pressure and temperature. The high-pressure steam generated in one stage is use as a heat source for the subsequent stage, thus maximizing energy efficiency.

Evaporator Vessels: The evaporator vessels or stages are the individual units where the evaporation takes place. Each stage is typically equip with heating surfaces, such as tubes or plates, to maximize heat transfer and evaporation efficiency.

Heat Source: The multi-effect evaporator relies on a heat source to provide the necessary energy for evaporation. This heat source is often steam, which is generate by boiling water using an external heat supply, such as a boiler. The high-pressure steam from one stage is condense and use as the heating medium in the subsequent stage.

Vapor Separation: As water evaporates in each stage, the resulting vapor is separate from the concentrate liquid. The vapor is collect and condense back into liquid form for reuse or further treatment, while the concentrate liquid continues to the next stage.

Concentrate Disposal: The concentrated liquid or brine that remains at the end of the multi-effect evaporator process contains a higher concentration of dissolve solids or contaminants. This concentrate may require further treatment or disposal, depending on the specific wastewater treatment goals and regulatory requirements.

Process Description

The wastewater or liquid solution enters the first stage of the evaporator, where heat is applie to vaporize a portion of the water. The resulting vapor passes to the next stage, which operates at a lower pressure. In each subsequent stage, more water is evaporate as the pressure decreases, while the remaining liquid becomes more concentrate with dissolve solids or contaminants.

Significance & Advantages

The multi-effect evaporator is commonly use in wastewater treatment processes to achieve water recovery, concentrate wastewater, or recover valuable substances from the wastewater stream. It offers several advantages, including energy efficiency, water conservation, and reduce wastewater volume for disposal. However, it should be note that multi-effect evaporators require careful design, operation, and maintenance to prevent scaling, fouling, and corrosion due to the concentrate liquid and high temperatures involve.

The specific design and configuration of a multi-effect evaporator may vary depending on the wastewater characteristics, treatment goals, and capacity requirements. Consulting with experts or manufacturers in the field can provide more specific information and guidance on implementing a multi-effect evaporator in a wastewater treatment system.