Stripper – Solvent Reovery System

In the context of wastewater treatment, a stripper with solvent recovery refers to a specialize unit or process used to remove volatile solvents or organic compounds from a liquid stream and recover them for reuse or recycling. This type of stripper is specifically designe to focus on the recovery of valuable solvents rather than complete removal or disposal.

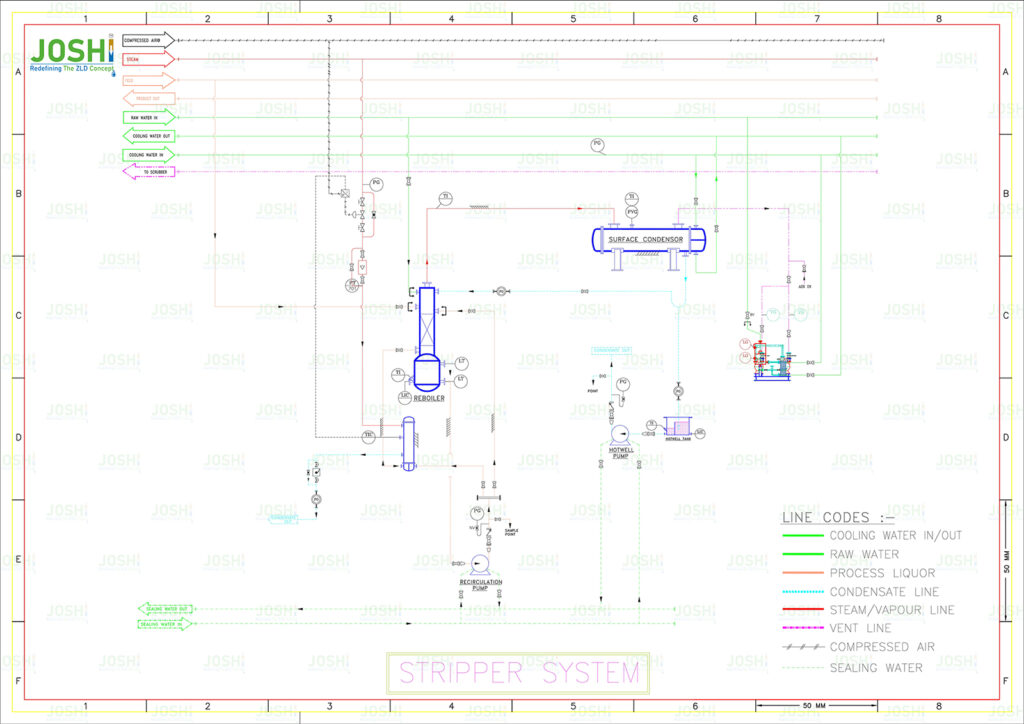

Process Mechanism

The solvent-laden vapor is then condense and collect for subsequent treatment or reuse, while the stripe liquid is typically treate further through a multiple-effect evaporator (MEE) and agitate thin film dryer (ATFD) to remove the dissolve salts and produce solid waste and recycled water.

Process Steps

Stripping: The stripper can be an air stripper, steam stripper, vacuum stripper, or a combination of these, depending on the specific requirements and characteristics of the solvents.

Vaporization: Heat or other energy sources are applie to the liquid stream to vaporize the solvents. The volatile solvents transfer from the liquid phase to the gas phase, leaving behind the stripe liquid.

Separation: The solvent-laden vapor is then direct to a condensation unit where it is cool, causing the solvents to condense back into a liquid form.

Stripped Liquid Treatment: The liquid stream that has been separate from the solvents is further treat to remove any residual contaminants or pollutants.

Significance & Advantages

Solvent Reuse: The recovery of solvents allows for their reuse within the industrial process, reducing the need for purchasing new solvents and promoting resource efficiency.

Cost Savings: The recovery and reuse of solvents can significantly reduce the operating costs associat with purchasing and disposing of solvents, thereby offering potential cost savings for the facility.

Environmental Sustainability: The solvent recovery process contributes to environmental sustainability by minimizing the release of solvents into the environment and reducing the overall carbon footprint associat with solvent production and disposal.

The design and implementation of a stripper with a solvent recovery system depend on factors such as the type and concentration of solvents, the volume and composition of the wastewater, the desire level of solvent recovery, and regulatory requirements.