Screw Press / Volute Press

In wastewater sludge handling, a screw press, also known as a screw dehydrator or sludge dewatering screw press, is a device use for dewatering sludge by utilizing the principle of continuous pressure filtration. It is an effective and widely use method for sludge dewatering in various wastewater treatment plants.

Process Mechanism

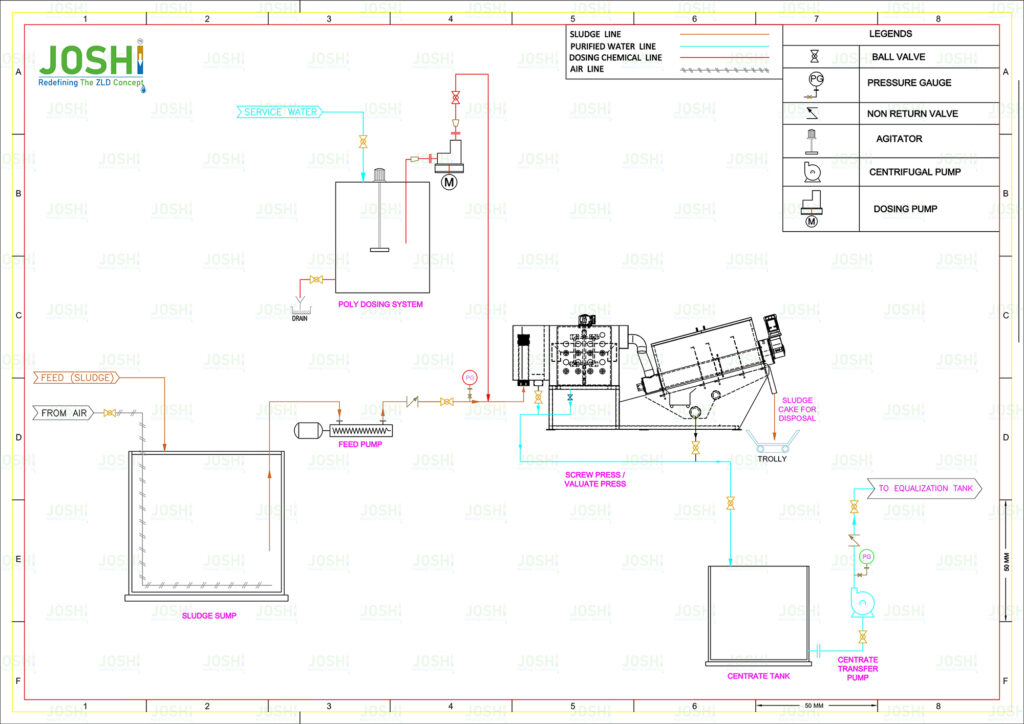

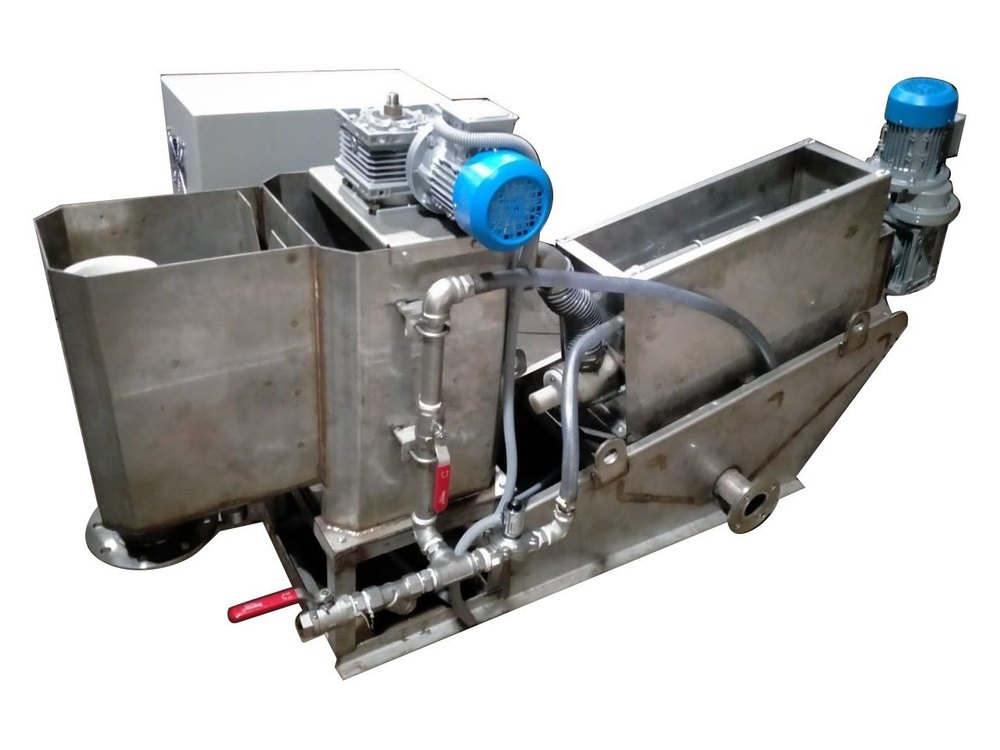

A screw press consists of a rotating screw or auger within a cylindrical screen or drum. The sludge is into the screw press, and as the screw rotates, it moves the sludge along the length of the screen. The rotating screw exerts pressure on the sludge, forcing the water to pass through the screen or drum, while the solid particles are retaine and compact.

Process Steps

Thickening: Prior to dewatering, the sludge may undergo a thickening process to increase the solids concentration.

Conditioning: Sometimes, sludge conditioning is necessary to improve dewatering efficiency.

Dewatering: The condition sludge is introduce into the screw press, where the rotating screw applies pressure to the sludge against the screen or drum.

Discharge: The dewater sludge cake is discharge from the screw press, typically through a chute or conveyor system, for further handling, drying, or disposal.

Significance & Advantages

Screw presses are known for their ability to handle a wide range of sludge types, including municipal wastewater sludge, industrial sludge, and biological sludge. They are efficient in achieving significant reductions in the moisture content of the sludge, resulting in a more concentrat and easier-to-handle product.

Screw presses are particularly suitable for applications where continuous dewatering is require, as they offer continuous operation and can handle high volumes of sludge. They are commonly use in wastewater treatment plants, food processing facilities, and various industries that generate sludge.