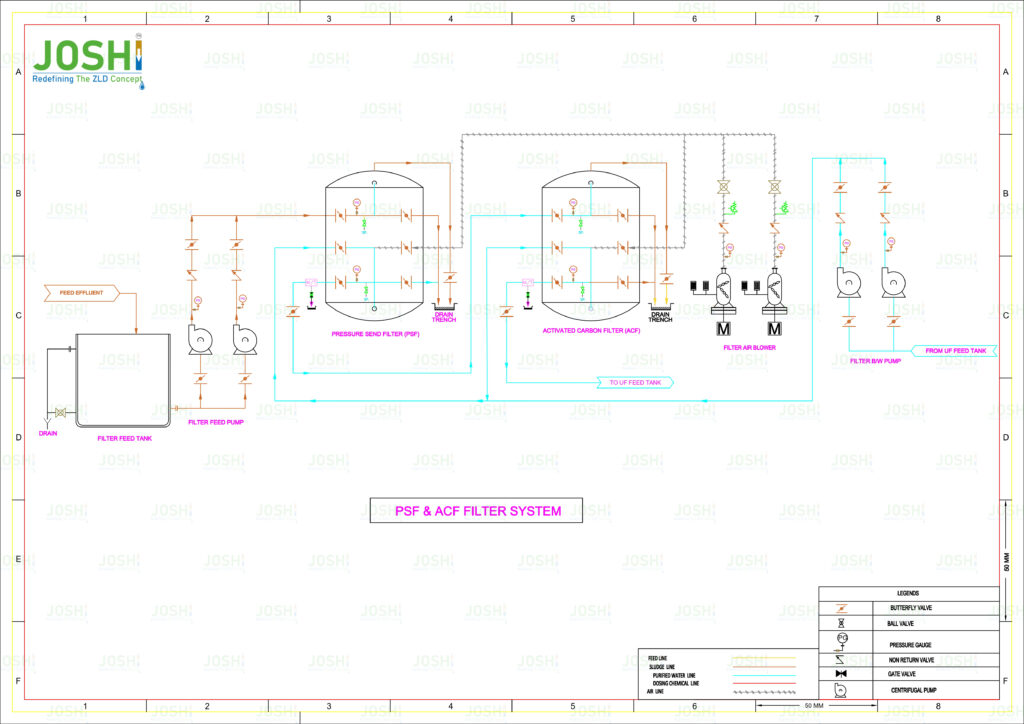

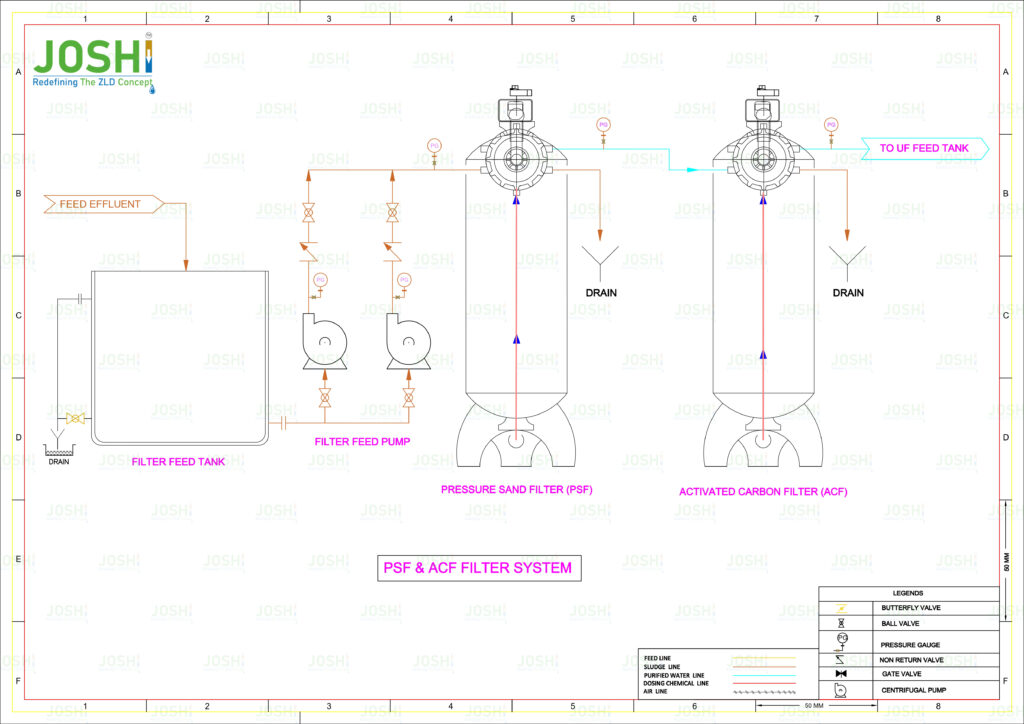

PSF - Pressure Sand Filter

A pressure sand filter is a type of filtration system use in wastewater treatment to remove suspend solids and turbidity from the water. It is an efficient and widely use method for solid-liquid separation in various industries and municipal water treatment plants.

System Components

Filter Vessel: The filter vessel is a cylindrical or rectangular tank that contains the filter media. It is design to withstand the operating pressure of the system. The vessel is usually made of steel or reinforce concrete and is equippe with inlet and outlet connections.

Filter Media: The filter media is the of granular material that performs the actual filtration. The most common filter media use in pressure sand filters is silica sand. The sand particles have different sizes, with larger particles at the top and finer particles at the bottom to create a gradient. The media retains suspend solids as the water passes through.

Distribution System: The distribution system evenly distributes the influent wastewater across the filter. It prevents channeling and ensures uniform flow distribution throughout the filter media. The distribution system typically consists of underdrains, lateral pipes, and nozzles.

Backwash System: To clean the filter media and remove accumulate solids, a backwash system is incorporate into the pressure sand filter. It typically includes a backwash pump, valves, and a wash water collection system. During backwashing, water flow is reverse, and a combination of air and water is used to agitate the filter and dislodge trapped particles.

Control System: A control system is employ to monitor and regulate the operation of the pressure sand filter. It controls the flow rates, backwashing cycles, and other parameters to optimize the filtration process and maintain efficient operation.

Process Description

Filtration: The influent wastewater enters the filter vessel through the inlet connection and is evenly distribute across the filter by the distribution system. As the water passes through the filter media, suspende solids and turbidity are trapp within the filter, while the clarifie water passes through and exits the filter vessel.

Accumulation of Solids: Over time, the suspende solids accumulate in the filter media, causing an increase in pressure drop across the filter. This indicates for backwashing to restore the filter’s efficiency.

Backwashing: When the pressure drop reaches a predetermine level, the control system initiates a backwash cycle. The backwash pump reverses the water flow and flushes the filter from the bottom to the top. This action dislodges and removes the trappe solids, which are carried out through the wash water collection system.

Rinse and Return to Service: After backwashing, a rinse cycle may be perform to settle the filter media and remove any remaining impurities. The filter is then return to the filtration mode, and the cycle continues.

Significance & Advantages

Efficient Solids Removal: The filter media effectively removes suspende solids, turbidity, and particulate matter from the wastewater, resulting in clarifie effluent.

Cost-Effective: Pressure sand filters are relatively simple in design, cost-effective to operate, and require minimal energy input.

Versatility: Pressure sand filters can be use in a wide range of applications and are suitable for various types of water and wastewater treatment.

Easy Maintenance: The backwashing process helps maintain the performance of the filter media and extends its lifespan. Routine maintenance involves periodic media cleaning and replacement.

Pressure sand filters are commonly use in pre-treatment stages of wastewater treatment processes, including industrial wastewater treatment, municipal water treatment, and water reclamation facilities. They contribute to the removal of suspend solids, turbidity reduction.

Target Impurities

- Suspended Solids

- Turbidity