Mechanical Vapor Recompressor (MVR)

A mechanical vapor recompressor (MVR) is an energy-saving device use in wastewater treatment processes, particularly in evaporators and concentration systems. It is design to reduce the energy consumption associate with vapor compression processes by utilizing the energy containe in the vapor stream.

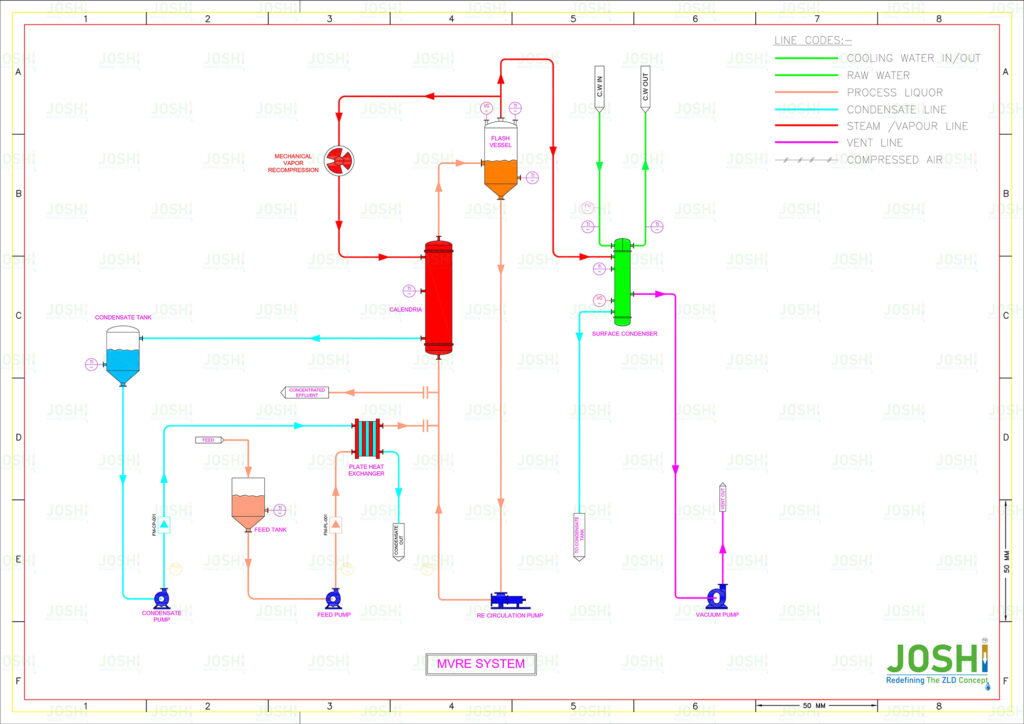

System Components

Compressor: The MVR system incorporates a compressor that compresses the vapor generate from the evaporator or concentrator. The compressor raises the pressure and temperature of the vapor, enabling it to be use as a heat source.

Heat Exchanger: After compression, the vapor passes through a heat exchanger where it transfers heat to the incoming or liquid stream. This heat exchange allows the vapor to condense and release its latent heat energy, which is then utilize in the evaporation or concentration process.

Condenser: The condense vapor is then collect in a condenser, where it returns to a liquid state. The condensate can be recycle back into the process or further treat.

Recompression: The compresse vapor from the condenser is recompresse by the compressor and sent back to the evaporator or concentrator as a heat source, completing the cycle.

Process Description

In wastewater treatment, MVR is often employ in conjunction with evaporators or concentrators to remove water from the wastewater or liquid stream. The basic principle of operation involves compressing vapor from the evaporator or concentrator and recompressing it back into the process as a heat source. This allows for the reuse of energy that would otherwise be lost during the condensation process.

Significance & Advantages

Energy Efficiency : By recompressing and reusing the vapor, the MVR system significantly reduces the energy requirements of the evaporation or concentration process. It allows for the recovery of heat energy that would otherwise be lost, resulting in overall energy savings.

Cost Savings: The reduce energy consumption of the MVR system translates into lower operating costs for wastewater treatment facilities. It can to significant savings in electricity or fuel expenses.

Environmental Benefits : The energy-saving nature of the MVR system contributes to a reduce carbon footprint and environmental impact. It promotes sustainable practices in wastewater treatment by optimizing energy usage.

Flexibility: The MVR system can be integrate into existing wastewater treatment processes, such as evaporators or concentrators, without requiring major modifications. It is adaptable to different system configurations and can be customize base on specific treatment requirements.

MVR systems are commonly utilize in various wastewater treatment applications, such as industrial wastewater treatment, zero-liquid discharge systems, and sludge concentration. They offer an efficient and cost-effective solution for water removal and concentration while minimizing energy consumption. However, it is important to note that the design and implementation of an MVR system should be tailore to the specific and characteristics of the wastewater treatment process.