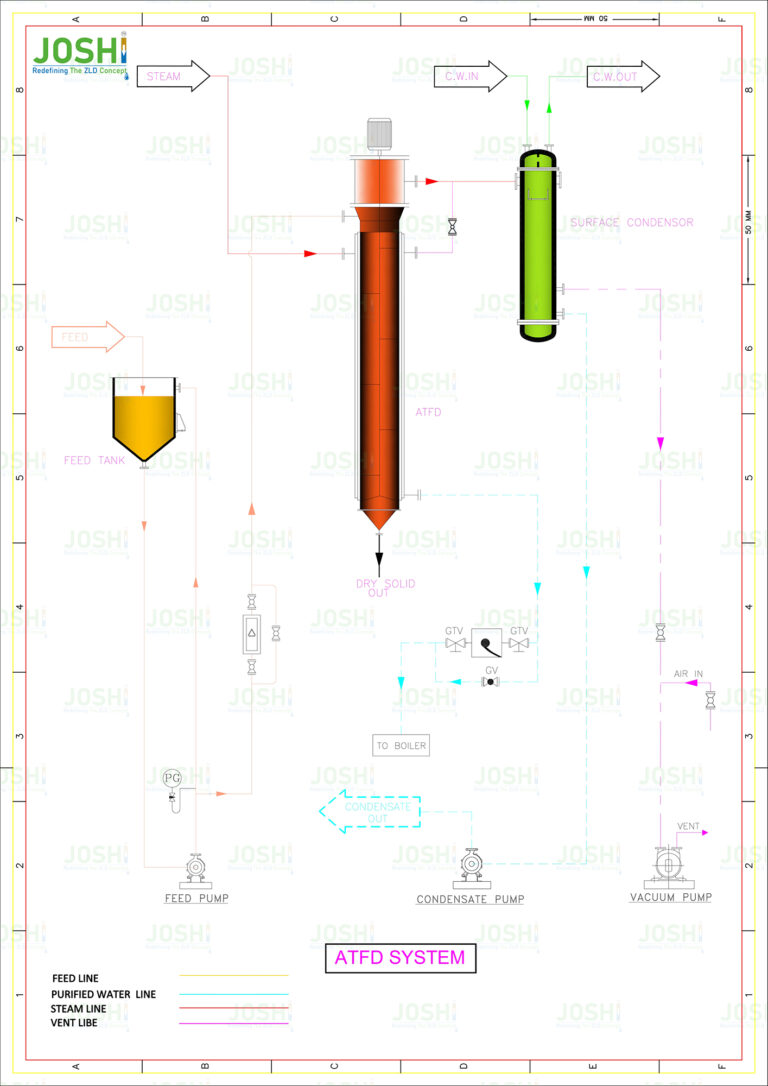

Agitated Thin Film Dryer (ATFD)

It is a device use to dry a solution of high TDS (total dissolve solids) water or products. It works by evaporating the water to make a concentrate liquid to dry powder or flakes by creating a thin film of the material over a heated surface. ATFD is commonly use in wastewater treatment associate with Zero Liquid Discharge System (ZLD), which aims to recover and reuse the water and eliminate any liquid waste.

System Components

Vessel: The vessel is typically made of stainless steel or other corrosion-resistant materials and is design to withstand high temperatures and pressure.

Agitation System: The ATFD is equippe with an agitation system, usually rotating blades or paddles, that continuously agitates the thin film of the liquid or slurry. This agitation helps maintain a uniform film thickness and enhances heat transfer efficiency.

Heating System: Heat is applie to the outer surface of the vessel to evaporate the water from the thin film.

Condenser: The evaporate water vapor is separate from the concentrate or drie product in the ATFD and is then condensed back into liquid form. The condenser allows for the recovery of the evaporate water, which can be reuse or further treat.

Product Collection: The concentrate or drie product remaining after evaporation is collect from the bottom of the ATFD vessel.

Process Description

The ATFD operates on the principle of creating a turbulent film of the liquid or slurry on the inner surface of a cylindrical vessel. This thin film is agitate or maintaine in motion by mechanical means, such as rotating blades or paddles. Heat is applie to the outer surface of the vessel to evaporate the water from the film, leaving behind a concentrate or drie product.

Significance & Advantages

ATFD offers advantages such as efficient heat transfer, low energy consumption, and a compact footprint compared to conventional evaporation or drying methods. However, the design and selection of an ATFD system should be base on the specific characteristics of the wastewater or slurry, desire product quality, and process requirements.