Extended Aeration (EA)

Extended aeration is a biological wastewater treatment process that relies on the use of aerobic microorganisms to break down organic pollutants in wastewater. It is commonly use for the treatment of municipal and industrial wastewater

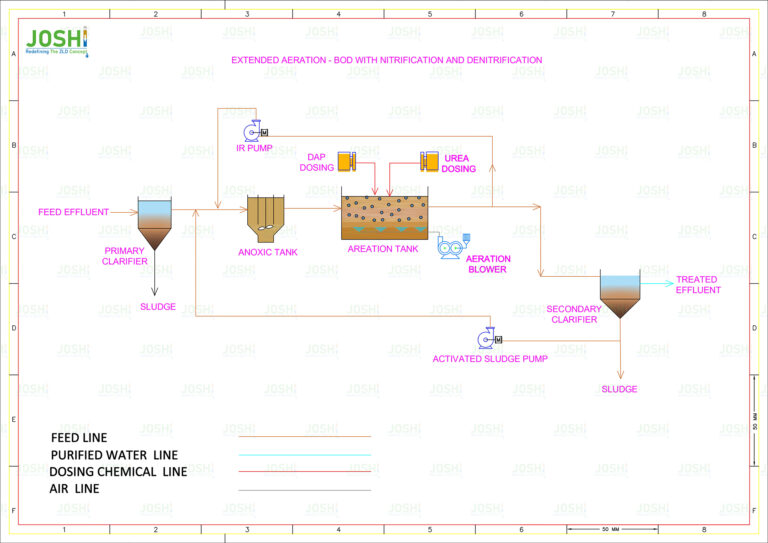

Process Steps

Wastewater Inflow : The process begins with the inflow of raw wastewater into the treatment facility. This wastewater typically contains a mixture of organic and inorganic contaminants.

Screening and Grit Removal : Large objects, debris, and grit are removed from the wastewater to prevent damage to downstream equipment and to improve the efficiency of the treatment process.

Primary Clarification : In some cases, the wastewater may pass through a primary clarifier to settle out heavier solids and reduce the organic load before it enters the extende aeration system.

Aeration Basin : The heart of the extend aeration process is the aeration basin, which is a large tank where the wastewater is mixed with activate sludge (a mixture of microorganisms) and aerate with oxygen. This encourages the growth of aerobic bacteria that consume organic matter in the wastewater.

Aeration : Air is continuously introduced into the aeration basin to provide the necessary oxygen for the microorganisms to carry out the biological treatment process. This promotes the growth and activity of bacteria, which break down the organic pollutants.

Mixing : Mechanical mixers or diffusers are used to ensure thorough mixing of the wastewater and activate sludge to maintain a consistent environment for the microorganisms.

Biomass Recirculation : Some of the activate sludge is recycle from the clarifier or secondary clarifier to the aeration basin to maintain the desire population of microorganisms and enhance treatment efficiency.

Monitoring and Control : The process is closely monitore for parameters such as dissolve oxygen concentration, pH levels, and microbial activity. Automate control systems adjust the aeration rate and other factors to optimize treatment performance.

Secondary Clarification : After the wastewater has spent sufficient time in the aeration basin (typically several hours to a day), it is direct to a secondary clarifier. Here, the treate water is allow to settle, and the activate sludge settles as well. The clarifie effluent is then collect from the top of the clarifier.

Sludge Handling : The sludge that settles in the secondary clarifier is either returne to the aeration basin as biomass recycle or remove from the system for further treatment or disposal.

Significance

Extende aeration is a significant and widely use wastewater treatment process with several key advantages and benefits, making it a preferre choice for many wastewater treatment facilities. Here are some of the significant aspects of extende aeration in wastewater treatment

Effective Organic Removal : Extende systems are highly efficient at removing organic pollutants from wastewater. They rely on aerobic microorganisms to break down complex organic compounds into simpler, stable substances. This process reduces the biological oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewater, making it environmentally safer to discharge into natural water bodies.

Consistent Treatment : Extende systems provide a stable and consistent treatment environment for microorganisms. The prolong aeration and mixing in the aeration basin ensure that the microorganisms have adequate time and resources to biologically degrade organic matter, even during variations in wastewater flow and composition.

Reduced Sludge Production : Extende aeration systems typically produce less sludge compared to other biological treatment processes. The slow growth and prolong contact time with microorganisms result in higher biomass yields and less frequent sludge wasting. This reduces the costs and efforts associate with sludge management.

Energy Efficiency: While extende aeration systems require continuous aeration, advances in aeration technology have made them more energy-efficient over the years. Modern diffusers and control systems allow for optimize oxygen transfer, reducing energy consumption.

Flexibility: Extende systems are versatile and can adapt to varying influent characteristics. They can handle changes in flow rates, organic loads, and shock loads, making them suitable for both municipal and industrial wastewater treatment applications.

Biological Nutrient Removal : Some extende aeration systems can be modifie to include processes like biological nutrient removal (BNR). This allows for the removal of nutrients like nitrogen and phosphorus, which are of environmental concern in many regions due to their role in eutrophication.

Odor Control : The prolong and biological activity in extende aeration basins often help control odors by promoting the oxidation of odor-causing compounds in the wastewater.

Compact Design : Extende systems can be design with a relatively small footprint compare to some other treatment processes, making them suitable for sites with limited space.

Reliability : These systems are known for their reliability and ease of operation. With proper maintenance and monitoring, extend systems can provide consistent and effective treatment for extende periods.

Compliance with Regulations : Extende aeration processes can be design and operate to meet stringent effluent quality standards and environmental regulations, ensuring that treat wastewater meets discharge requirements.

Cost-Effective: Extende aeration systems can offer cost-effective solutions for wastewater treatment, especially for smaller municipalities and industrial facilities, due to lower capital and operational costs compare to more complex treatment processes.

In summary, extende plays a significant role in wastewater treatment by efficiently removing organic contaminants, providing consistent and reliable treatment, reducing sludge production, and offering flexibility to adapt to changing conditions. Its effectiveness and versatility make it a valuable tool for ensuring the safe and responsible treatment of wastewater before its release into the environment.

Targeted Impurities

- COD

- BOD

- Nutrient

- NO2

- NO3

- Phosphorus