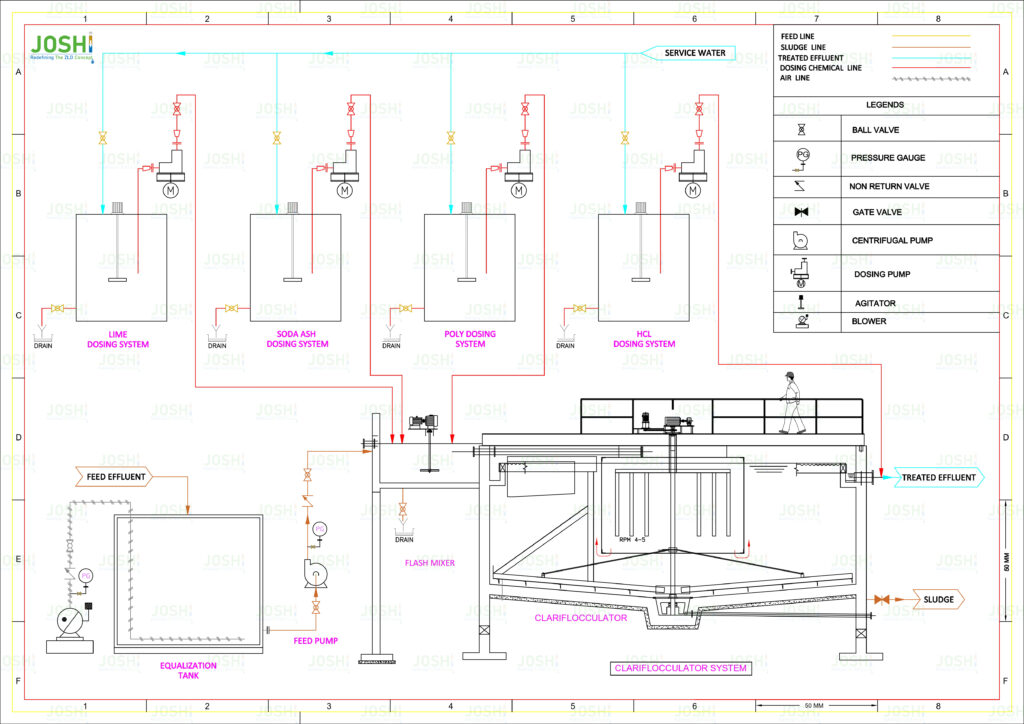

Clariflocculator

A clariflocculator, also known as a flocculation clarifier or combined flocculator-clarifier, is a wastewater treatment unit that combines both flocculation and sedimentation processes in a single tank. It is designed to promote the formation of flocs and facilitate their settling to remove suspend solids, colloidal particles, and other impurities from wastewater.

Process Steps and Key Functions

Flocculation: The wastewater enters the clariflocculator, where gentle mixing or stirring is applie to promote the formation of flocs. Coagulants and flocculants are often add at this stage to aid in the process.

Settling Zone: After the flocculation process, the wastewater enters a settling zone within the clariflocculator. The settling zone provides a calm and quiescent environment, allowing the flocs to separate from the liquid and settle to the bottom of the tank.

Sludge Collection: The settled flocs form a layer of sludge at the bottom of the clariflocculator, known as primary sludge. This sludge is periodically collected and removed using sludge rakes, scrapers, or other mechanisms and directed to further treatment or disposal processes.

Clarified Effluent: The clarifie wastewater, with reduce suspend solids concentration, flows out of the clariflocculator through effluent weirs or outlets located near the top of the tank.

Significance

The combination of flocculation and settling processes within a single tank makes the clariflocculator a compact and efficient unit in wastewater treatment plants. It allows for the removal of suspended solids and other impurities in a single treatment step, reducing the footprint and operational complexity of the treatment system.

Clariflocculators are commonly use in both industrial and municipal wastewater treatment plants. They can be particularly effective in applications where the wastewater contains a high concentration of suspend solids or requires enhance removal efficiency.

Baffles: Baffles are vertical or inclined plates install inside the tank to create flow patterns that promote the settling of solids. They help to control the flow direction and prevent short-circuiting, which is the direct flow of water from the inlet to the outlet without proper settling.

Targeted Impurities

- TSS

- Turbidity

- BOD

- Colloidal Particles

- Partial Color

- grit

- Chemical Sludge

- Hardness

- Heavy Metals