CRP – Caustic Recovery Plant

A caustic recovery plant, also known as a caustic regeneration plant, is a specialize facility use in wastewater treatment to recover and recycle caustic soda (sodium hydroxide) from spent caustic solutions. It is commonly employ in industries where caustic soda is use as a chemical reagent or cleaning agent in various processes.

System Components

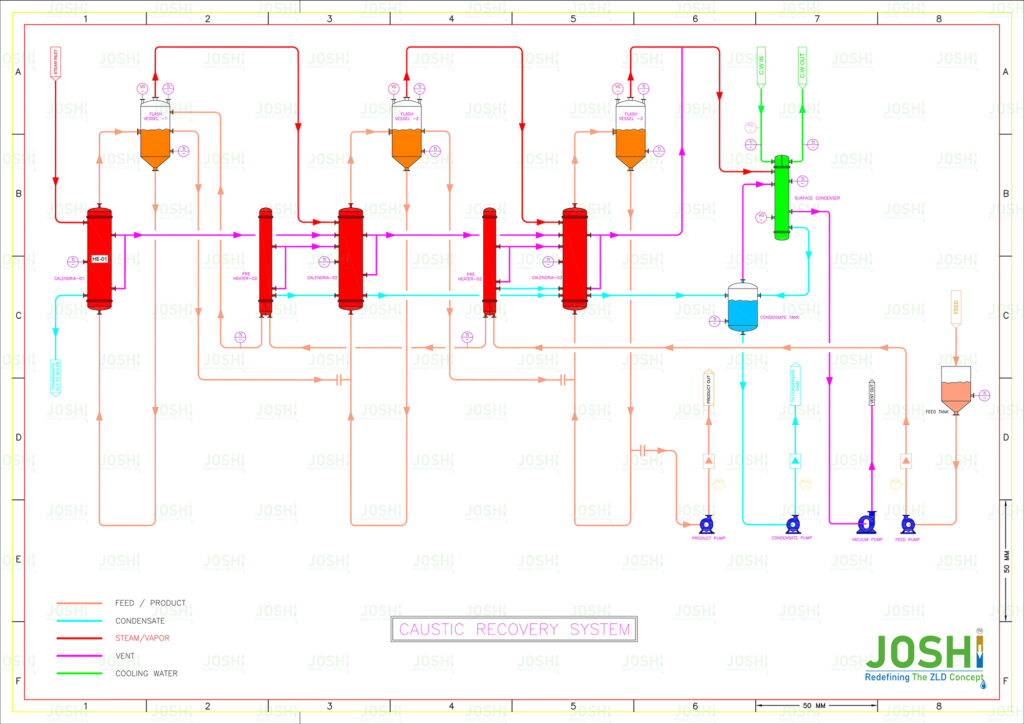

The specific components and processes involve in a caustic recovery plant can vary depending on the composition of the spent caustic solution and the desire outcome. However, some common elements may include.

Pre-treatment: The spent caustic solution is typically pre-treate to remove solid particles, oil, grease, or other impurities that could interfere with the recovery process. Pre-treatment may involve processes such as filtration, settling, or chemical treatment.

pH Adjustment: The pH of the spent caustic solution is adjust to create suitable conditions for the subsequent caustic recovery process. This may involve neutralization or acidification, depending on the specific requirements of the process.

Caustic Regeneration: The regeneration of caustic soda is typically achieve through a process known as caustic stripping or caustic distillation. In this process, the spent caustic solution is heat under control conditions, causing the caustic soda to vaporize. The vapors are then condense and collect as regenerate caustic soda, while any impurities or contaminants remain behind.

Impurity Removal: Depending on the specific contaminants present in the spent caustic solution, additional treatment steps may be require to remove impurities. This may involve processes such as filtration, chemical precipitation, or ion exchange to achieve the desire purity of the regenerated caustic soda.

Post-treatment: After the caustic regeneration process, the treate caustic solution may undergo post-treatment to ensure compliance with quality standards or specific process requirements. This may involve pH adjustment, further filtration, or chemical conditioning before the caustic soda is ready for reuse.

Process Phenomenon

The caustic recovery plant aims to reduce the consumption of fresh caustic soda and minimize the generation of hazardous waste by recovering and reusing the spent caustic solution. The process involves the treatment of the spent caustic solution to remove contaminants and regenerate the caustic soda, making it suitable for reuse.

Significance & Advantages

Caustic Soda Reuse: The recovery and recycling of caustic soda allow for its reuse within the industrial processes, reducing fresh caustic soda and promoting resource efficiency.

Cost Savings: The caustic recovery plant can significantly reduce the operating costs associat with purchasing new caustic soda and disposing of spent caustic solutions.

Environmental Impact Reduction: The caustic recovery process helps minimize the generation of hazardous waste and reduces the overall environmental impact associated with caustic soda production and disposal.

The design and implementation of a caustic recovery plant depend on factors such as the composition of the spent caustic solution, the volume of waste generate, the desire caustic soda recovery efficiency, and regulatory requirements. Consulting with experts in the field or engaging with specialize companies that provide caustic recovery solutions can assist in designing an efficient and effective plant for a specific wastewater treatment application.